Values-Based Pricing

To celebrate spring this year, we want to do something a little different. We want to share a behind-the-scenes look at the costs that go into furniture manufacturing in America from the vantage point of our tiny studio in the woods.

For those of you who don’t know our work, we are a family-owned design and manufacturing studio on Bainbridge Island across the Salish Sea from Seattle. For the past twelve years, we have made furniture, lighting, textiles and objects from our home and then eventually a commercial studio space. We have had five full-time and two part-time employees as well as several interns since our inception, but there have been many stretches of time (including this one) where we have worked solo as a husband and wife team.

In the early days of our business, we felt insecure about our pricing. We were uncomfortable about making things that were considered expensive. We don’t get asked as much as we used to about our pricing. These days, the majority of our sales are to architects and interior designers who do the hard work of educating their clients about why things cost what they do. That said, we thought it might be helpful to share more about how our pricing comes together.

For this exercise, we are going to use our popular Dish Coffee Table in black as an example. Since we sell most of our work to the design trade, we’ll use our trade list price, $3,281.00, as the starting point. Trade pricing is a design industry standard that ranges by manufacturer. Our trade price is 15% less than our retail price. Offering trade pricing allows architects and interior designers an opportunity to earn a markup on the products that they source, sample, purchase and install. If you are curious about how trade charging works, this is a good read.

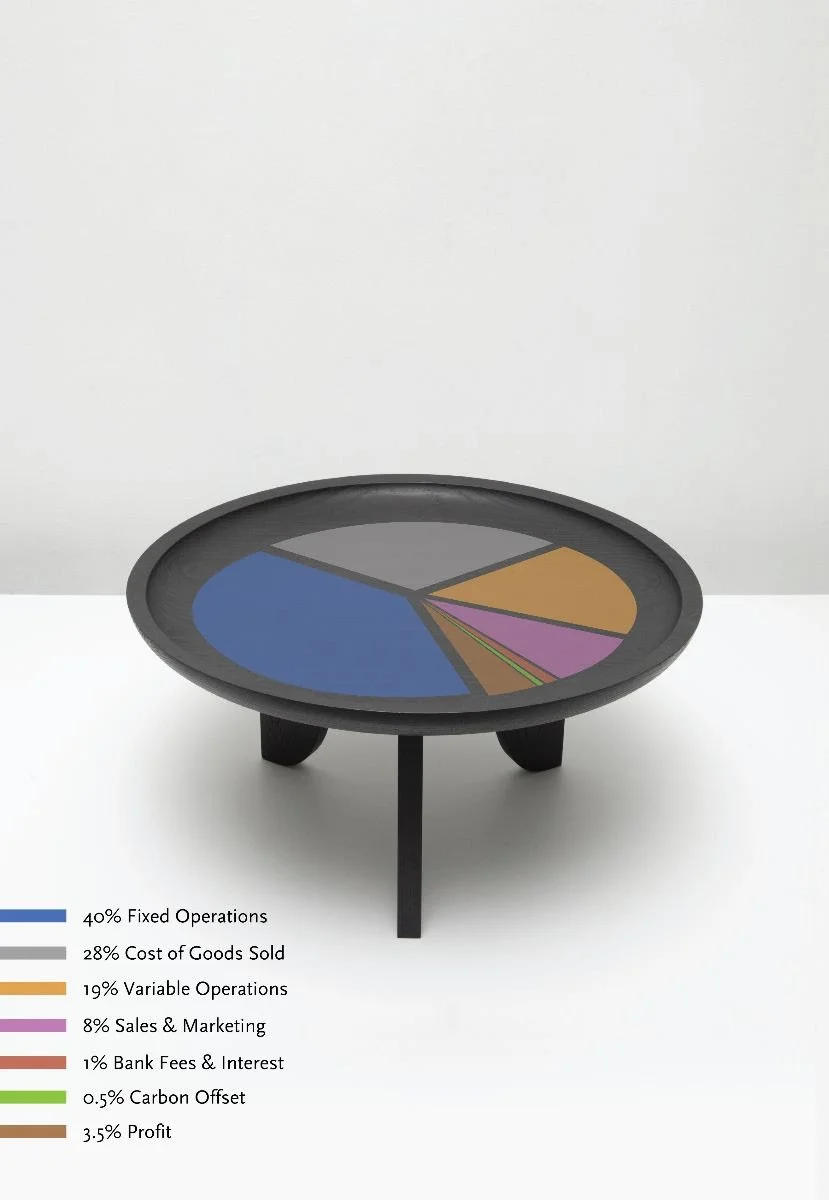

And, now, here is a breakdown of all the costs that go into producing our Dish Coffee Table:

40% Fixed Operations ($1312.40 per table)

These are the fixed costs required to run our studio and manufacturing shop. The biggest portion goes to salaries, followed by rent, benefits and insurance. This year was complex as we had reduced staff due to COVID but also increased rent and insurance as we leased a larger manufacturing shop.

28% Cost of Goods Sold ($918.68 per table)

These are the raw materials and manufactured parts that go into each piece. For our Dish Coffee Table, this includes FSC-certified ash which we purchase from a lumber distributor in Port Townsend. Currently, we work with a small shop in Seattle that does the rough shaping of our tabletops on their CNC router. We mill the legs in-house, cut tenons and do all the sanding and hand-applied finishing. In addition to this, there are the costs of the non-toxic glue, mineral stain and plant-based oil and wax finish as well as all the tools and parts (think sandpaper and brushes) required to complete this work safely and at a high level of craft.

19% Variable Operations ($623.39 per table)

These are the variable costs required to run our studio and manufacturing shop. They include everything from taxes, utilities, small tools and equipment, office supplies, sampling costs, shipping, bookkeeping and tax services, software, donations, snacks for the studio and more. These costs change from year to year based on our sales as well as how efficiently we run the studio.

8% Sales & Marketing ($262.48 per table)

This year we did not attend any trade shows or have any product launches due to COVID, so this cost is predominantly our showroom fee, website hosting costs, sending out our monthly newsletter and all the eco-friendly print materials that get included in our shipments.

1% Bank Fees & Interest ($32.81 per table)

This includes any interest paid on credit cards, loans or lines of credit. It also includes credit card processing fees and other bank charges.

0.5% Carbon Offset ($16.41 per table)

We use this amount to offset the carbon we estimate is being released into our atmosphere as we produce each table from the raw materials used all the way through to shipping it to its new home. We offset the carbon produced by our entire business via certified carbon credits purchased through Climate Neutral.

3.5% Profit ($114.84 per table)

This is the amount left over after everything else is covered. Not a huge amount by any stretch, but within all the costs listed above is our ability to responsibly source the best materials, work with talented people, pay ourselves a living wage, offset the environmental costs of doing business and build a creative practice together as a family on the island that we call home. We feel grateful just to pull it off.

Like most small businesses, 2020 was a unique year. Though our individual pieces make a small profit, that isn’t our full financial story. Even before the pandemic, we were making plans for 2020 which included investing in new equipment, moving into a larger manufacturing shop, committing to 100% renewable energy and offsetting our carbon footprint. We anticipated that our expenses would probably overrun our sales resulting in a loss, and they did.

What we did not predict was a 20% loss of sales as well. This was our first loss in sales in seven years, so it was a disappointment for sure. That said, as we look out onto the landscape of vanished small businesses, shuttered storefronts and so much collective grief, we know it could have been worse. We also know that this experience has changed us as a business and as a family and has deepened our commitment to social and environmental responsibility.

Why share all of this in a newsletter? For us, there is no better way to express our values than math. In showing how we invest every dollar that flows through our business, we hope to illustrate what we care about most. Being far from perfect, this math also gives us a chance to be accountable and to see where we can make improvements.

Thanks for following along, friends. We hope this new season finds you safe and well.